Uncompromising safety and comfort

Wed, 06 Aug 2014

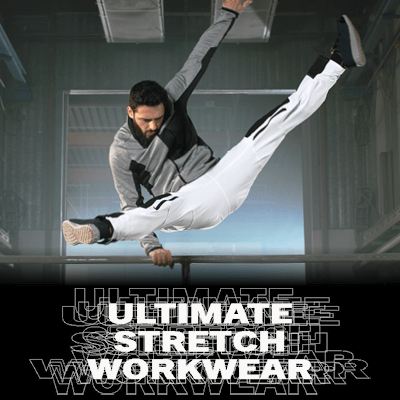

For many years, multi-protective clothing has almost exclusively been designed to protect the wearer against external elements such as arcs, sparks, etc., and it still must do so. But, now comes a range of protective clothing where more than just safety has been paramount to the development process. The internal comfort and an ergonomic fit, allowing greater mobility and functionality such as pockets, straps and adjustment options has also been brought into focus.

Optimally, workwear should be tested within the workplace before it is mass-produced. And that’s exactly what MASCOT® WORKWEAR has done with the new MASCOT® MULTISAFE range. The result is nine thoroughly tested products with uncompromising safety, functionality and design.

Workwear that you don’t notice

"Our focus is to provide our customers with workwear in which they not only feel safe, but are able to forget that they are wearing protective-wear. You rarely notice clothing when everything works and supports the body’s natural movements and when there are proper functions and well-placed pockets," assesses CEO Michael Grosbøl, who has closely followed the development of the new MASCOT® MULTISAFE range.

![]()

Industry-tested before production

The range has been in development for more than 18 months. One of the most time-consuming phases - but also the most important – was that of the wearer trial period in which MASCOT’s product development department sent workwear to work throughout Europe. Employees of utilities, and of the gas, oil and electricity industries, have tested the clothes in their daily work, and they have continually provided feedback and suggestions on eventual changes that MASCOT has then developed further. For example, user suggestions led to an improved position of the ruler pocket, which greatly influenced the overall comfort. The test wearers were so tired of their workwear having ruler pockets that sat too far back on the leg, which meant that one sat on their tools when sitting, and that one felt the tools every time they would kneel or squat. MASCOT had a long dialogue with the certification institute and found a solution that could not only be certified but that also excited the testers as it considerably increases comfort during all movements.

Flame retardant for the life of the product

Concurrent with the industry wearer trials, MASCOTs own laboratories were working feverishly to find the fabric that had just the right combination of properties. "More than 40 different types of fabric were tested for everything from shrinkage to wear resistance and tensile strength”, says Michael Grosbøl and stresses that it benefits wearers to choose the best fabric type: "Unlike many other suppliers, MASCOT is using a 100% 'inherent' fabric, where it is the fibers of the fabric that contain the flame retardant properties. This means that the flame retardant properties do not dissipate after repeated washing, as can be the case with products where the flame retardant property is applied to the surface - wearers of such clothing are not able to detect when the 'safety disappears'.

![]()

More choose multi-protective workwear

It is not everyone that needs certified anti-static, acid resistant and flame retardant workwear that also protects against arc and the occasional welding. But, more and more industries are becoming aware of how the proper workwear can reduce the risk of certain types of injuries. In addition to electricians, it is especially those that work with the storage and distribution of energy (gas, wind, electric and oil) that are now using multi-protective clothing. These employees are often outside and close to running machinery and trucks. As such, the clothing may also need to be windproof, waterproof and breathable, as well as fluorescent and with reflectors. The new MASCOT® MULTISAFE has it all. In the range are a winter jacket and winter trousers, each of which is approved to no less than nine different standards.

For the rest of the year, the range includes fluorescent work trousers, bib & brace and a work jacket, all of which, in addition to the usual standards, are also treated with a stain-resistant coating to keeps the fluorescent clothing clean and thus visible over time. There are also four products intended as inside layers: a t-shirt, a sweatshirt, a long-sleeved functional undershirt and a pair of functional underwear. All four are antistatic, flame retardant and sewn with flame retardant thread.

![]()

The fluorescent clothing is approved under the new, tougher standard EN ISO 20471. In addition, the products are equipped with even more reflective material than the norm prescribes. All the fluorescent products have the chemical norm EN 13034 and, as one of the few in the industry, both of MASCOTs jackets are class 2 in the electric arc norm EN 61482-1-2.

The trousers, jackets, bib & brace, T-shirt and sweatshirt are currently in stock, while the winter wear and functional underwear will be in stock September 2014.